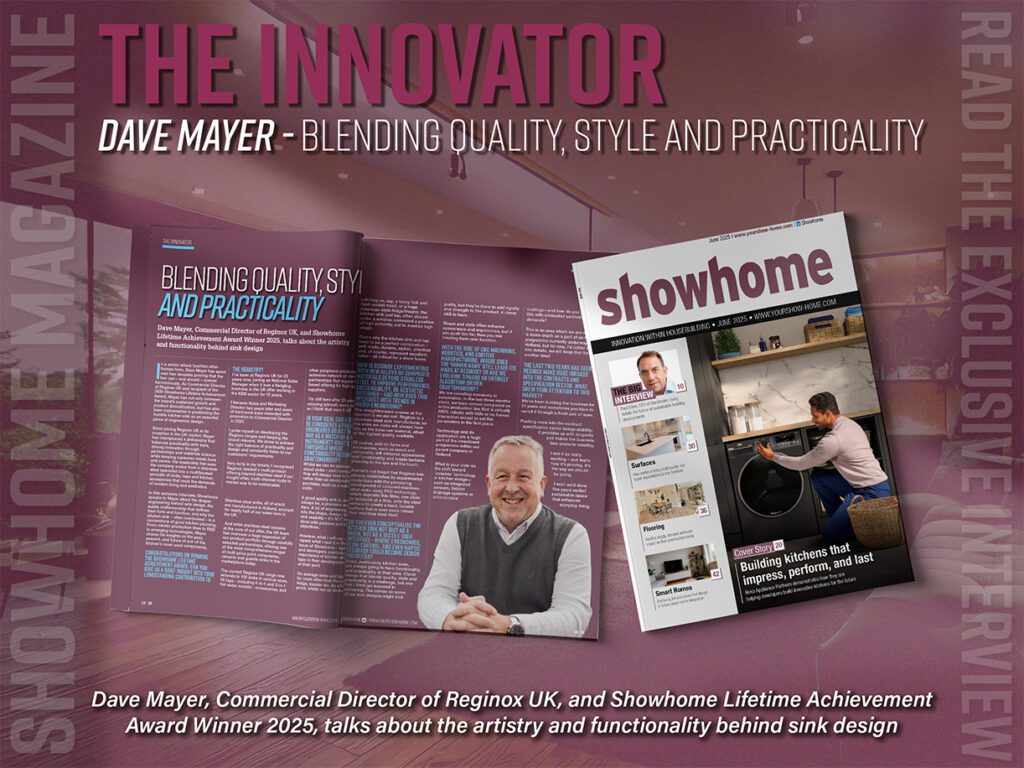

Dave Mayer, Commercial Director of Reginox UK, and Showhome Lifetime Achievement Award Winner 2025, talks about the artistry and functionality behind sink design

In a sector where function often trumps form, Dave Mayer has spent over two decades proving that the two can – and should – coexist harmoniously. As Commercial Director of Reginox UK and recipient of the 2025 Showhome Lifetime Achievement Award, Mayer has not only overseen the brand’s sustained growth and product diversification, but has also been instrumental in positioning the humble kitchen sink as an essential piece of engineered design.

Since joining Reginox UK at its inception in the UK market, Mayer has championed a philosophy that balances practicality with style, driving innovation through partnerships and materials science while keeping customer needs front and centre. His leadership has seen the company evolve from a stainless-steel specialist into a multifaceted provider of sinks, taps and kitchen accessories that meet the demands of modern living and aesthetics.

In this exclusive interview, Showhome speaks to Mayer about the deeper engineering behind sink design, the subtle craftsmanship that defines their form and function, and why the kitchen sink – often overlooked – is a cornerstone of good kitchen planning. From robotic production lines to R&D in emerging technologies, Mayer shares his insights on the past, present, and future of one of the kitchen’s most used components.

Congratulations on winning the Showhome Lifetime Achievement Award. Can you give us a brief insight into your longstanding contribution to the industry?

I’ve been at Reginox UK for 25 years now, joining as National Sales Manager when it was a fledgling business in the UK after working in the KBB sector for 15 years.

I became Sales and Marketing Director two years later and years of hard work were rewarded with promotion to Commercial Director in 2021.

I pride myself on developing the Reginox ranges and keeping the brand relevant. We strive to achieve the right balance of practicality and design and constantly listen to our customers’ requirements.

Very early in my tenure, I recognised Reginox needed a multi-product offering beyond stainless steel if our sought-after, multi-channel route to market was to be sustainable.

Stainless steel sinks, all of which are manufactured in Holland, account for nearly half of our sales here in the UK.

And while stainless steel remains at the core of our offer, the UK team has overseen a huge expansion of our product portfolio through carefully selected partnerships, offering one of the most comprehensive ranges of multi price point composites, ceramic and granite sinks in the marketplace today.

The current Reginox UK range now extends to 150 sinks in various sizes, 56 taps – including 4-in-1 and 3-in-1 hot water models – accessories, and other peripheral products sold via an extensive network of strong trading partnerships that support our brand-based offering for high quality suppliers.

I’m still here after 25 years and enjoying (almost) every day – so I think that says it all!

In your view, can a kitchen sink be considered a precision-engineered object in the same way as a watch or a musical instrument? What’s the threshold where functionality becomes craftsmanship?

Whilst we can be passionate about sinks – and I certainly am – they will always tend to be a necessity rather than an emotionally-driven purchase, such as a watch or a rare violin.

A good quality sink is, and should always be, a precision engineered item. A lot of engineering skills go into the shape, design, strength and usability – it’s NOT random, it’s done with purpose and clear objectives.

However, what I will say – and I’ll repeat what I said it in the last issue of Showhome – builders and developers overlooking the importance of kitchen sinks and taps in their developments do so at their peril.

On average sinks and taps are used far more often than the cooker, hob, fridge, toaster etc. As a kitchen focal point, whilst not as obviously eye-catching as, say, a fancy hob and flash cooker hood, or a huge American-style fridge/freezer, the kitchen sink and tap, often placed under a window, command a position of high authority, not to mention high usage.

That’s why the kitchen sink and tap need to be a perfect combination – well made, durable, stylish, practical and, of course, represent excellent value – all critical for a show home.

How is Reginox experimenting with new alloys or composite materials beyond stainless steel to improve performance, sustainability, or aesthetic outcomes – and how does this intersect with trends in micro-engineering?

The straightforward answer at the moment is we are not. Reginox is a stainless-steel sink manufacturer, so the sinks we make will always have this as the base raw material, albeit of the highest quality available.

Of course, add on items and accessories, such as wood and composite, will enhance appearance and functionality and create textures pleasing to the eye and the touch.

And let’s not forget that Reginox has already established its experimental credentials with the pioneering development of coloured stainless-steel sinks using PVD technology, which deposits thin films, one atom or molecule at a time, onto the steel surface to create a hard, durable surface that is even more robust than stainless steel itself.

Do you ever conceptualise the kitchen sink not just as a basin, but as a tactile user interface – where ergonomics, flow control, and even haptic feedback could become design priorities?

Sinks, particularly kitchen sinks, are always going to have functionality and practicality at their core. Clever design that blends quality, style and practicality is a challenge, but one that I think we succeed in achieving. The curves on some of our sink designs might look pretty, but they’re there to add rigidity and strength to the product. A clever skill to have.

Shape and style often enhance appearance and ergonomics, but if you push too far, then you risk creating form over function.

With the rise of CNC machining, robotics, and additive manufacturing, where does the ‘human hand’ still leave its mark at Reginox? Or are we evolving toward an entirely algorithm-driven craftsmanship?

We are investing massively in automation. In the last three months alone, we have almost completed an entire production line that is virtually 100% robotic with little or no human interaction except to set the parameters in the first place.

Technology and its application are a huge part of the investment programme within our parent company in Holland.